charpy impact test copper alloy|charpy impact testing : services The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .

WEB1 de fev. de 2024 · Here are the best official FireStick apps for watching anime that are available in the Amazon App Store. 1. Crunchyroll. Considered an anime haven by its fans, Crunchyroll has established .

{plog:ftitle_list}

webMídias de comparação é o sistema que o Fatal Model usa visando gerar mais credibilidade aos perfis.. Todas as mídias de comparação são analisadas por nossa equipe. Lembre-se: sempre que ficar com dúvida se as mídias de algum acompanhante são verdadeiras, venha aqui e de uma espiada para comparar.

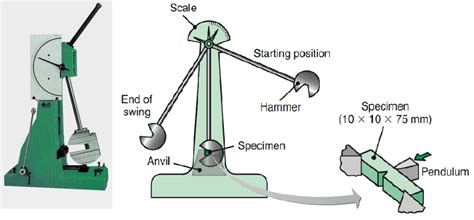

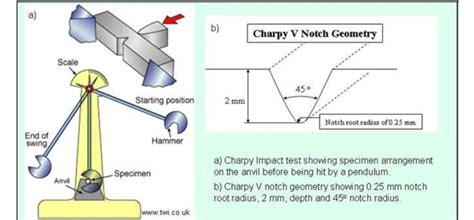

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM Charpy impact test is the most common technique for evaluating the impact toughness of materials under high strain rates (~10 3 s −1) 1. It has been reported that the impact toughness.In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

undersized charpy impact test

charpy v notch impact test

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

Charpy impact testing is a low-cost and reliable test method which is commonly required by the construction codes for fracture-critical structures such as bridges and pressure .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure In the Charpy impact test, a notched specimen is . Charpy testing is a method for determining the relative impact strength of metals. It is also known as the Charpy V notch test. This testing method was developed in the 1940s by S.B. Russell and G. Charpy.Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).

iphone 7 plus otterbox defender drop test

charpy impact testing

iphone 7 plus red drop test

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to .Charpy impact test is the most common technique for evaluating the impact toughness of materials under high strain rates ( ε ~10 3 s −1 ) 1 . It has been reported that the impact toughness are . The ultimate tensile strength, yield strength, elongation and reduction of area were obtained from the average of three repeated testing results. Impact toughness was tested on an impact tester at room temperature, using standard Charpy V-notch impact samples with a size of 10 mm × 10 mm × 55 mm. Impact toughness presented in this study was . The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

cobalt-based alloys; copper-based alloys-brass-bronze iron based alloys; aluminum-based alloys; titanium-based alloys; MACHINE SHOP DEPARTMENT . Machine Flattening Rings Machine & Surface Grind Macro Specimens PHYSICAL TESTING DEPARTMENT; Welder Certification Charpy Impact Testing Welding Procedures Hardness Testing Tensile Testing .

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significantThe Charpy Impact test is a high strain-rate method used to assess the impact toughness of metals and alloys. . Copper and its alloys, such as brass and bronze, may undergo impact testing to evaluate their suitability for various applications, including electrical components, plumbing fixtures, and architectural elements. Impact testing helps . High alloy steels exhibit much higher impact toughness than low alloy steels. . Uniaxial tensile test and Charpy V-notch impact test were conducted by using Instron machine (WDT-10) and tensile .

The impact property is one of the most significant mechanical properties for metallic materials. In the current work, a soft-hard copper-brass block with a high yield strength of ~320 MPa and good . The CVN impact specimens (size: 55 × 10 × 10 mm) were subjected to impact testing at 20 °C by an impact tester with a capability of 750 J, following the thermal aging process. Two parallel . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

charpy impact test temperature

Impact toughness at ambient and cryogenic temperatures was investigated with systematic fracture analyses for CuFeMn and Al 15 (CuFeMn) 85 (at%) immiscible medium-entropy alloys. These two types of alloys exhibited different impact toughness behavior at different temperatures, while exhibiting higher impact toughness values than those of dual .

Stacking fault energy (SFE) of high- and medium-entropy alloys (HEAs and MEAs) can be tuned by tailoring the constituent. In this work, we prepared a non-equiatomic Cr 26 Mn 20 Fe 20 Co 20 Ni 14 HEA with low SFE and investigated the Charpy impact behavior at 298 and 77 K, respectively. The Cr 26 Mn 20 Fe 20 Co 20 Ni 14 HEA performs an inverse .

Charpy impact testing (also known as the Charpy v-notch test) is a high strain rate testing standard that determines the amount of energy absorbed by a material during a fault (Kim et al., 2015).

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to . geometry modified for our testing due to limitation in casting thickness in BMG alloys. 19 Figure 2-2: A schematic of a Charpy impact test. . Two 1 cm diameter copper coils were mounted on a plate 70 mm apart, with their midpoint located at the impact . The impact property is one of the most significant mechanical properties for metallic materials. In the current work, a soft–hard copper–brass block with a high yield strength of ~320 MPa and good uniform elongation of .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

The Charpy impact test behavior of base metal, weld metal, and heat‐affected zone for 6061‐T6 and 7075‐T651 aluminum alloy welds was analyzed.Metals and Alloys TESTING. The MES metal test lab performs mechanical, metallurgical, chemical, environmental, failure analysis, and corrosion testing of metal materials. METAL TESTING CAPABILITIES. Our proven mechanical test lab provides controlled tensile strength testing, hardness testing, Charpy impact resistance, shear, strain, compression .

If the material is not exempt, Charpy V-notch impact test results shall meet the minimum impact energy requirements of ASME BPVC, Section VIII, Division 1, UG-84. . K500 Monel is a nickel copper alloy and has good mechanical properties for shafts down to -320 F. It does not require an impact test unless specified by the user to this limit.

iphone 7 plus silicone case drop test

Present study was carried out to investigate the mechanical properties of newly developed cast aluminum alloy with addition of (1.0 aged heat treatment, AHT %) of copper and (1.0 AHT %) magnesium .Longitudinal orientation. The three toughness values for CarTech AerMet 100 alloy obviously vary considerably in magnitude. Compare the values mentioned for CVN impact energy and fracture toughness with the area under the stress-strain curve of 4291 (calculated as (16.1) x .

Impact fracture testing of NUCu-60 steel shows its remarkable dynamic fracture toughness; Charpy samples did not fracture down to -79°C (-110°F), they bent over in the Charpy apparatus as the hammer swung through. . (60 KJ/inch). In fracture tests at -30°C(-22°F) the average Charpy absorbed impact energy was 124 J (91 ft-lb). The .

Nearly 400 different kinds of copper alloys have been designed to match specific environments and applications. Pure copper has high thermal and electrical conductivity. . Charpy impact ( V-notch) 100 J: 73.8 ft-lb: Hardness, Brinell (500 kg) 110: 110: Hardness, Rockwell B: 77: 77: . Mechanical & Physical Properties TestingAccording to the Charpy impact test results, the third sample having 1000 °C casting temperature had higher breaking energy compared to samples casted at 1200 °C and 1100 °C. The number of studies investigating crack propagation mechanisms in titanium and titanium alloys during a Charpy impact toughness test is very limited. Therefore, an in-depth discussion/comparison of the crack propagation behaviour of PM-produced Ti-6Al-4V with an ingot-produced and heat-treated alloy is not possible, except for a comparison .

Resultado da Fangame fnaf plus Fnaf Plus doom RC Para celular e pc #fnaf #fnafplus #fangamefnaf. INSANE_DEV @INSANE_DEV. Follow. 1 year ago. Fangame fnaf plus. Fnaf Plus doom RC. Para celular e pc. #fnaf #fnafplus #fangamefnaf. Five Nights at Freddy's. Five Nights at Freddy's Creations .

charpy impact test copper alloy|charpy impact testing